SIMS Sample Preparation

Polishing and coating

All samples must be polished -- in general the surface should have a <1 micron surface roughness. Furthermore, any sample which is not intrinsically an electrical conductor must be coated with a conductive film prior to analysis. Unless working with a special application, we deposit a high-purity, ~100 nm thick gold film on the cleaned sample surface.

Sample Size

The Cameca ims-series Ion Microprobes accept two types of samples: (1) thin samples which can be spring loaded into a masked sample holder and (2) circular thick samples which must have an OD of 1 inch and which are locked into the holder using small set screws. Thin samples must be at least 6 mm x 6 mm but are also limited to no larger than the 1 inch diameter of the sample holder; they should be no more than 3 mm in thickness; the back side of the sample should be flat and parallel to the polished front side on which the analysis is to be performed. For thick samples, we recommend using a 1 inch OD aluminum ring within which the sample is cast in high vacuum compatible epoxy (we use Buehler No. 20-8130-032 cold-set epoxy resin and No. 20-8132-008 epoxy hardener). The surface roughness of the area being analyzed should be less than 1 µm -- rougher sample may be analyzed, but the data quality can be degraded by having a poorly prepared surface.

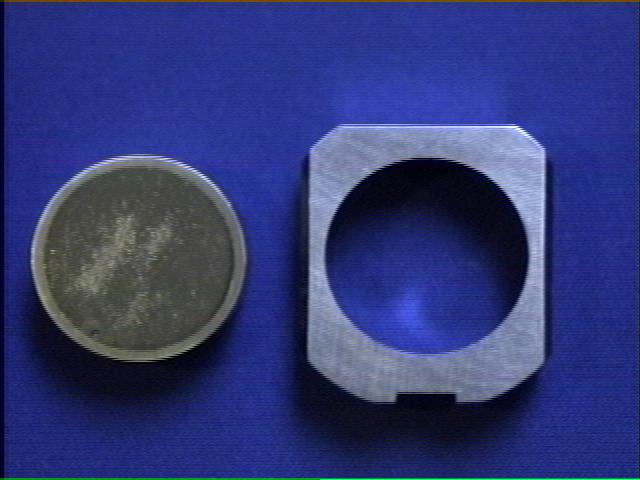

Grain mounts and 1" diameter polished thin sections

Left side shows <250 µm crystals embedded in epoxy which is cast within an aluminum ring with a 1 inch outside diameter. The sample has been polished and gold coated. Right side show the Cameca 1 inch diameter stainless steel sample holder. The polished sample is placed in the holder from the backside and is then locked into the holder using set-screws located at the upper corners of the sample holder.

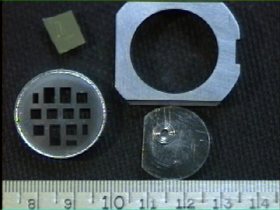

Mounting Semi-Conductors or Other Small, Polished Samples

Upper Left: small piece of coated silicon wafer, maximum allowable size 2 x 2 cm; minimum allowable size 7 x 7 mm

Lower Left: tantalum mask which has a set screw for loading the Al plug>

Lower Right: aluminum plug and small spring for backloading the Ta mask

Upper Right: Cameca 1 inch diameter stainless steel sample holder into which the loaded mask is placed. Scale at bottom is in centimeters

The surface of the sample must be clean. Those materials which are not intrinsically clean as the result of their manufacture are ultrasoniced for ~5 minutes in ethanol and then dried in an oven at ~80 Celsius. We coat samples which are non-conducting with a thin, high purity gold film prior to analysis. If placing a gold film on the sample is surface is not acceptable then we can arrange for a carbon film to be used instead.